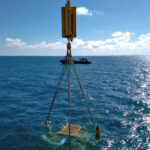

Subsea Landing

As subsea structures get larger and more complex, landing speed of subsea structures becomes an increasingly important topic. Cranemaster has been used extensively to reduce motion for subsea lifting operations. Boom tip movements are picked up by the stroke of the Cranemaster unit and thereby limiting the load movements.

Operational Challenges

The operational challenges related to subsea landing includes:

- Limited operational weather window to reach required vertical landing speed.

- Structures with landing speed limitations. Exceeding these might cause overstress within the structures.

- Landing of structures with tight angular tolerance.

- Rapid heeling of vessel during landing of heavy loads.

Cranemaster Benefits

By using a Cranemaster unit during the subsea landing, the operation will benefit from:

- Reduction of landing speed.

- Possibility to maintain tension in wire during landing phase.

- Reduction of peak loads in case of re-lifting.

- Prevention of rapid heeling of vessel during landing of heavy loads.

Subsea Landing With and Without Cranemaster

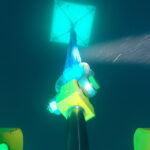

Two 700T Cranemaster units are used in parallel. Actual observed forces and movements corresponded well to the Orcaflex simulation.

Without Cranemaster:

Maximum landing speed = -0,7 m/s

Maximum crane tension = 2000 ton

With Cranemaster:

Maximum landing speed = -0,1 m/s

Maximum crane tension = 840 ton

No slack observed in the rigging

Case Studies