Posted in Cranemaster News

Shock Absorption for Pile Run Protection

Posted in Cranemaster News

The installation of piles is an act of balancing the pile driving force and the soil’s resistance to driving. The installer wants to overcome the soil resistance to be able to drive the pile, while at the same time being in control of the driving process.

The risks associated with a sudden drop of the pile hammers includes:

- Overloading of the crane, the rigging and the connection to the hammer

- If it’s not a pile hammer breakdown, there may be a need for inspection and recertification

- Loss of operational time and project delays.

60% decrease in dynamic hook load with shock absorber

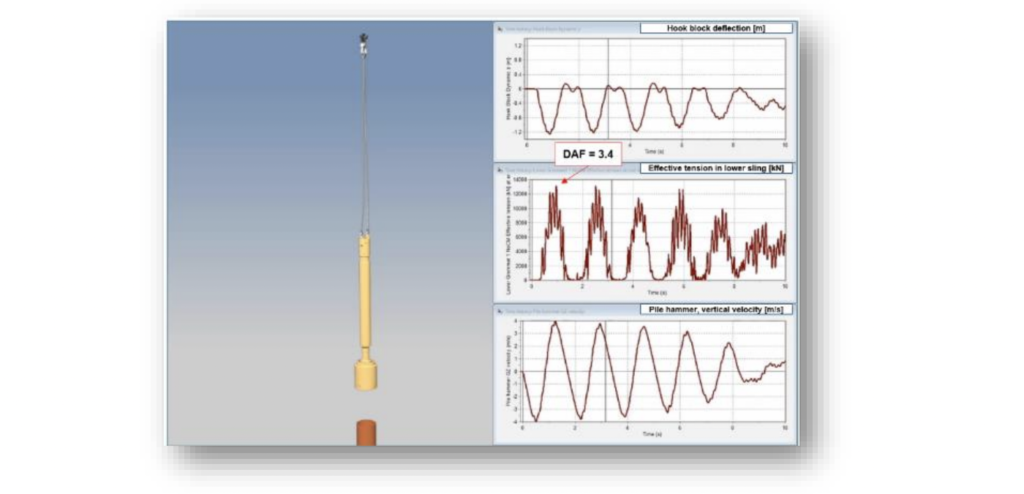

As an example, the calculated dynamics associated with a 780 tonne pile hammer falling 750 mm resulted in a dynamic hook load of 2700 tonnes (see figure 1).

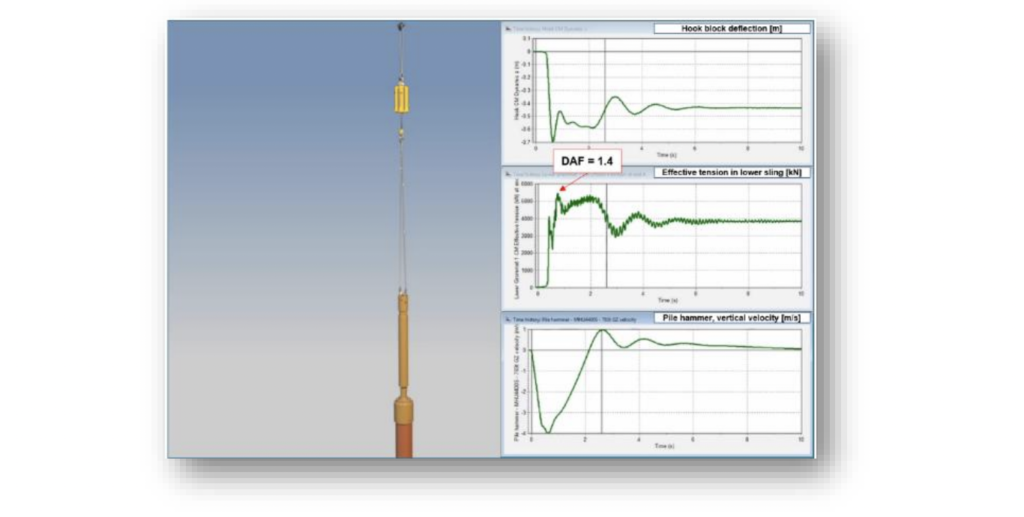

By adding a shock absorber, the dynamic hook load is significantly redused. In the example with the 780 tonne pile hammer falling 750 mm, the dynamic hook load is only 1100 tonnes when using the shock absorber – an impressive 60% reduction (see figure 2).

By adding a shock absorber, the dynamic hook load is significantly redused.

Sondre Gonsholt, CTO Cranemaster

Hence, using a shock absorber in the rigging ensures that potential dynamics are kept within acceptable limits. This leads to a significant mitigation of risk.

Summary

- Pile driving involves the risk of severe dynamic overload.

- Ignoring the risk can be costly.

- Shock absorption can be used as risk mitigation.

- Early assessment and planning are important.

Want to know more about how a shock absorber can mitigate risks in your pile driving project? Get in touch!

Read more: Pile Run Protection With Cranemasters