Transfer Lifts

Removal of peak loads in crane and rigging

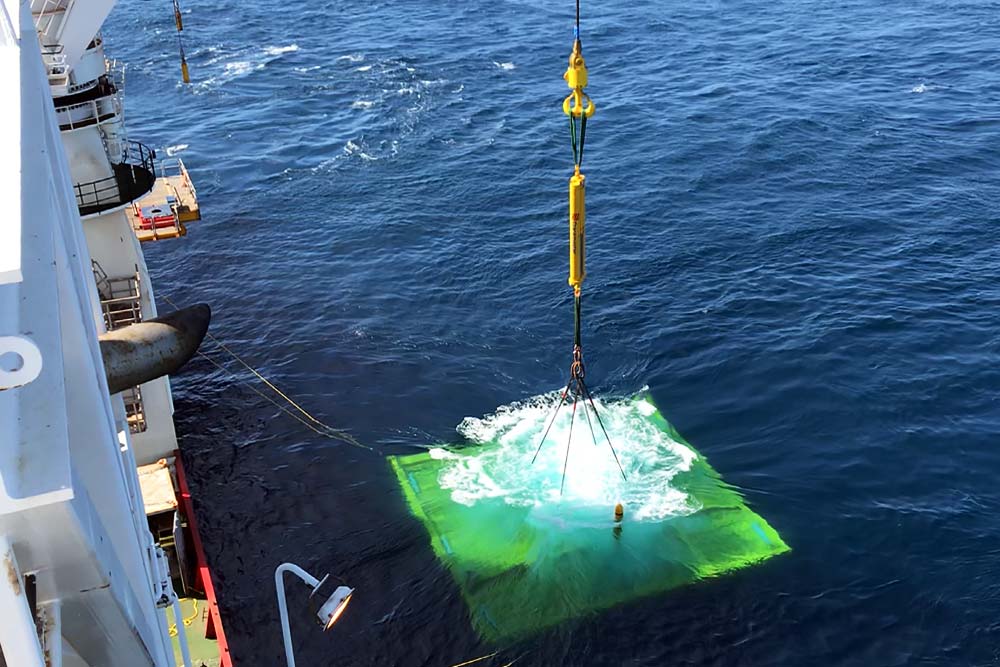

Splash Zone Crossing

Reduction of dynamic forces and slack slings when lowering large objects through the splash zone

Pile Run Protection

Absorption of shock loads in case of pile runs.

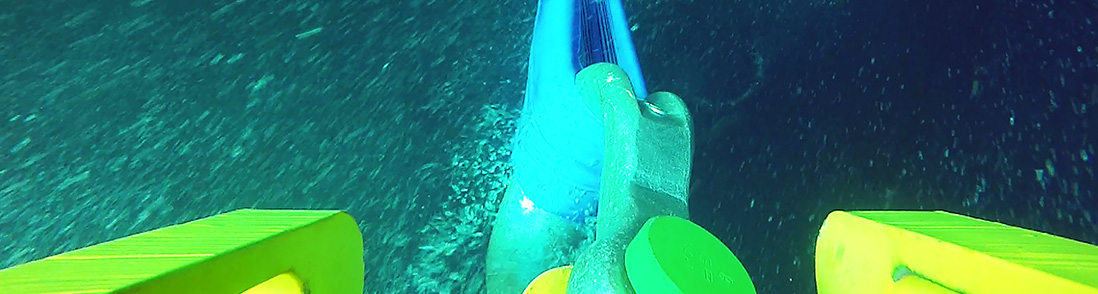

Subsea Landing

Reduction of landing speed and maintained tension in wire during landing phase

Load Chart Improvement

Lifting capacity maintained despite increasing wave heights

Tension Control

Constant tension despite vessel movements

Resonance Avoidance

Absorption of uncontrolled dynamic forces and escalating movements during deep water operations

Quick Lift

No re-contact after lift-off